advertisement

Gallery

Product Information

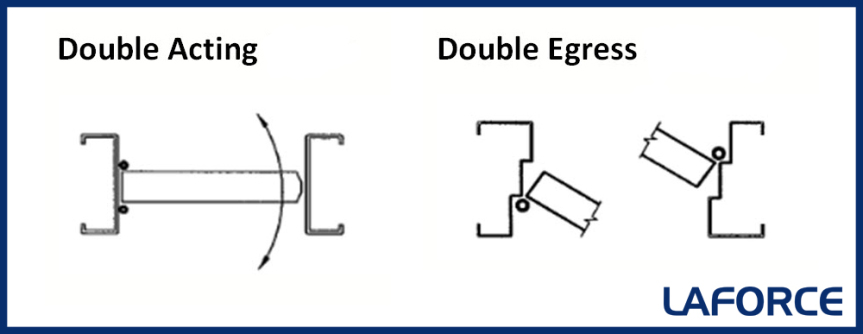

“Double Egress” Doors vs. “Double Acting” Doors

Double egress doors and double acting doors are commonly confused. Read on to discover the differences in application and purpose, and contact LaForce with any additional questions! We also encourage you to save our Door, Frame, and Hardware Glossary for handy reference.

Double Acting Doors

Definition:

A double acting door, also known as a double swinging door or impact traffic door, is a single door or a pair of doors in which the door(s) is able to swing in both directions.

Purpose:

These doors are a cost-effective solution for fast and efficient two-way movement through an opening where a visual and/or sound barrier is necessary to separate two areas.

Frame/Hardware Application:

The door is hung on double acting hinges, or center hung pivots in a “cased open” frame (i.e. no integral stops) which allows the door to swing freely in both directions.

Areas of Use:

Shipping/receiving areas, restaurant kitchens, supermarkets, grocery stores, warehouses, storage facilities, etc.

Notes:

Common add-on hardware for this type of opening application includes bumper strips, spring bumpers, impact/base plates, and jamb guards. This extra hardware can help prevent damage to the high traffic doors that are often knocked and bumped.

Double Egress Doors

Definition:

This type of application is always a pair of doors in which each leaf can only swing in the opposite direction.

Purpose:

These doors are used to control corridor traffic by providing quick, but safe exit and entry into an area; because the traffic on the opposite side of the door does not collide with the oncoming traffic.

Frame/Hardware Application:

The doors are often given hardware that only allows operation from the push side which helps control the traffic flow. A special profile frame is necessary to allow the doors to swing in the opposite direction.

Rolling Gates

Rolling gates are a type of slide gate. Cantilever gates are the most popular type of slide gate. Cantilever gates use a roller that attach to support post with no rollers or wheels touching the ground. The cantilever gate is cantilevered over the opening, hence the name cantilever. This is the perfect gate for any automated application as it does not contact the ground and operates well in adverse weather. It is controlled entirely by the rollers that guide it.

Unfortunately, cantilever gates are normally elevated off the ground due to the guide wheels and rollers that are placed below the frame of the gate to support it. Cantilever gates have to be installed level. This is required in accordance with ASTM 2200; it is vital to provide a safe installation. Cantilever gates roll freely and are very heavy. These roll freely with the use of sealed ball bearing rollers. A slope down hill can cause the cantilever gate to take-off as it starts to roll down hill. This is very dangerous and could cause harm to anyone or anything in its way. So always evaluate the elevation when considering a cantilever gate. IF the elevations at any point of the travel of the gate is greater than the elevation at the gate support post; you must raise the gate to maintain a level gate installation. Therefore, if you have slopes, valleys in any part of the travel, a cantilever gates are not a good option.

If the opening is sloped across the opening, or if you have an elevation on the side opening where the gate is to store, you might want to consider a rolling slide gate. Rolling gates us rear guide wheels that attach to the gate that run on a track attached to the adjoining fence. this track will follow the slope or rising elevation allowing the gate to also follow this slope as it travels along the track. There is a wheel assembly at the front of the gate. This assembly is located at the bottom of the gate and travels on the ground. thus, if you have a sloped opening, the gate will travel with the slope. With the combination of the rear guide wheels and front wheel assembly, the gate will travel through any sloped opening.

The bad new, Rolling gates are not a good option for automation. With the wheel traveling on the ground; ground conditions; variations in slope, and sever weather can affect the travel making the final destination unknown. A rolling gate should be closed manually to control the direction of the gate when closing.

Rolling gates use a wide range of hardware that include a front wheel assembly or double wheel carrier, locking device, rear wheels assemblies and track brackets. Installation and the cost of the hardware make a rolling gate not as a competitively priced as a swing gate but slightly less than a cantilever gate.

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.