advertisement

Gallery

Product Information

Repair is the technical aspect of rehabilitation. It refers to the modification of a structure, partly or wholly which is damaged in appearance or serviceability. Repair is the technical aspect of rehabilitation.

Grout

is a composite material generally consisting of water, cement, and sand. It is typically used for filling voids under machines or other structural elements, sealing joints and openings in surfaces and reinforcing existing structures

STRUCTURAL CONCRETE REPAIRS

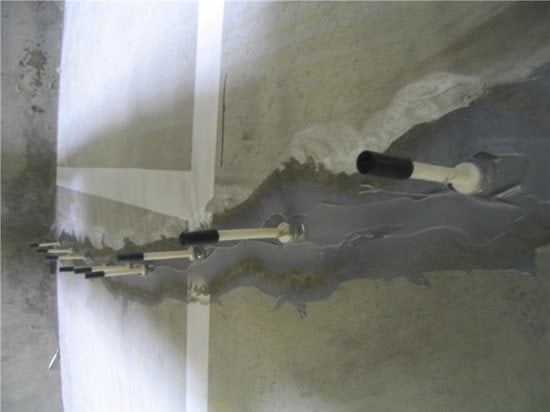

Cracks are sealed and epoxy injected to restore strength.

When a crack affects the performance of the structure, then we will repair it to restore its structural properties. Epoxy injection is typically the basis for this type of repair, with or without added reinforcement. The injected epoxy is actually stronger than the concrete and can restore the concrete strength, but if there is an underlying problem, such as an overloaded structure or some movement condition, the concrete will simply crack again in another location.

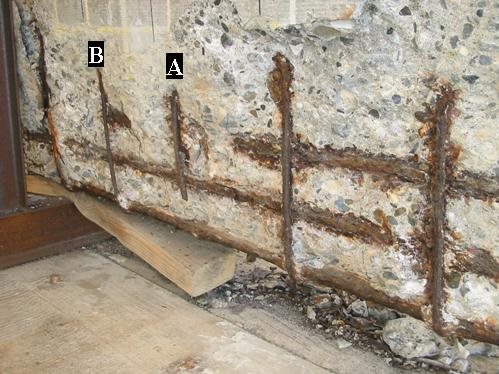

When reinforcement corrodes and delaminates the concrete covering,

reinforced concrete can quickly lose strength. Oregon State University

To use epoxy injection to repair a crack, the crack is first cleaned by vacuuming or flushing with water to get out any dirt or contamination. The cracks on the surface are then sealed with an epoxy gel to prevent the injected epoxy from running out. Injection and venting ports are installed and the epoxy is injected. High pressure is not used since that could actually widen the cracks. Once the cracks have been filled, the ports and surface seals are removed, typically by grinding the surfaces flush with the concrete matrix. Epoxy injection has also been successfully used to repair surface delamination of slabs. Learn more about crack injection.

When concrete is too deteriorated for epoxy injection, then all unsound concrete is removed and new concrete is placed. Obviously, great care must be taken to stabilize the structure prior to removing the damaged concrete, by shoring or other means. Once again, the secret to successful repairs of this sort is in the preparation. No deteriorated concrete can remain and anyplace where reinforcing is corroded, the concrete must be removed from completely around the bars, providing and at least ¾-inch clearance on all sides. The steel is then cleaned to remove any loose corrosion products (rust). If the cross section of the steel has been reduced significantly, new steel will be tied to the existing steel prior to replacing the concrete.

Full-depth repairs require new steel to be installed and tied into the existing concrete. Applied Engineering & Technology

If strengthening is needed, there are a variety of techniques used, including simply increasing the size of the concrete member and external reinforcing. External reinforcing is often accomplished by bonding some sort of flexible reinforcement, like carbon or glass fibers, to the exterior of the concrete member then covering it with placed concrete, troweled-on concrete, or shotcrete.

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.