advertisement

Gallery

Product Information

A systemic approach to waterproofing foundations

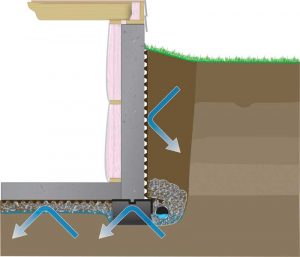

Illustration of a capillary break.

A waterproofing membrane will resist hydrostatic pressure, thereby preventing water from entering the building. A drainboard provides relief from hydrostatic pressure by giving water a space to flow into, preventing much of the hydrostatic pressure from acting on the wall. Once the drainboard guides the water down to the footing (the lowest level of the foundation), the perimeter drain can carry the water away from the building, where it can no longer do any damage.

Capillary rise

Just as a dry sponge soaks up water, concrete and concrete masonry unit (CMU) walls have the capacity to wick up moisture from the footings. As Joseph Lstiburek from the Building Science Corporation says, the theoretical limit of the capillary rise in concrete is 10 km (6 mi). The so-called ‘capillary rise’ is often a serious challenge in structures with concrete footings and foundation walls. According to green building expert Martin Holladay, capillary rise can contribute up to 57 L (15 gal) of water a day to a building’s interior moisture load.

that the phenomenon of capillary rise occurs when the forces of adhesion are stronger than the forces of cohesion, meaning the attraction between water and wall molecules exceeds the attraction of water molecules to one another. This capillary action causes moisture in damp soil to migrate first to the footings and then up into the foundation walls.

Installation of a footing barrier.

In many instances, moisture can travel several feet before the forces of cohesion and adhesion are in equilibrium. As mentioned, capillary rise may add numerous gallons of water to the moisture load inside a home. The contrast in capillarity from one material to another can even be striking. Water may rise as much as 6 m (20 ft) in certain clay soils, but only inches in crushed stone.

Capillary breaks

To avoid the adverse consequences of such moisture migration, a capillary break should be placed between the footing and the wall. Architects, designers, and contractors have two primary options when it comes to capillary breaks between basement walls and concrete footings: membranes and fluid-applied waterproofing.

Contractors should follow the manufacturer recommendations and wait before using fluid-applied products on new concrete footings. Some products may require up to a four-week wait, as the concrete must fully cure before application. The concern is such products will be prematurely applied, potentially compromising effectiveness through improper bonding and cracking. Of course, scheduling pressures are all too common. Architects who stipulate the application of a membrane as a capillary break while the concrete pour is still fresh can avoid this problem.

To facilitate the use of a membrane as a capillary break, a concrete wall should be keyed to a footing through the use of a keyway. Vertical rebar can be employed for increased structural integrity when necessary, and it is also required in earthquake zones. When vertical rebar is present, contractors often opt for fluid-applied products. However, membranes still remain a viable option.

Although there are claims an appropriate concrete additive can reduce capillary rise, many manufacturers are unwilling to make such a broad promise. For a different solution, some builders choose polyethylene sheeting under footings. However, bonding issues can make it unreliable.

Without capillary breaks between footings and the foundation walls, unhealthy conditions such as mold and poor IAQ can develop. Capillarity can also lead to the premature deterioration of materials sensitive to moisture and mold growth. In residential buildings, the effects often manifest in the form of black mold around the lowest one or two feet of the interior drywall.

Specifying the right drainage board

Drainage composites are broadly specified as critical components of a successful below-grade moisture management system. However, they often are seen as adjuncts to the main waterproofing or dampproofing course, tagged onto specifications as mere accessories. Too often treated as a commodity, the drainage products are viewed as interchangeable without any consideration of their ability to meet the required performance preferences, as outlined by the building owner.

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.