advertisement

Brand Information

Hilton Metal Forgin g is a very young company which has grown by leaps and bounds as one of the leading manufacturer & distributors of steel forged flanges, fittings & oilfield and marine products for both the domestic & international markets as per ASTM/ ASME/MSS/API/AWWA/DIN/EN/ AUSTRALIAN/RUSSIAN AND NACE Standards. We procure the best steel and use state-of-the-art machinery resulting in better quality forged flanges and fittings. Exhaustive quality checks are done at every stage right from conception, designing and manufacturing ensuring high accuracy in terms of composition, mechanical properties, dimensions and delivery. We are also capable to provide special custom forgings as per our customers’ drawings and specifications.

g is a very young company which has grown by leaps and bounds as one of the leading manufacturer & distributors of steel forged flanges, fittings & oilfield and marine products for both the domestic & international markets as per ASTM/ ASME/MSS/API/AWWA/DIN/EN/ AUSTRALIAN/RUSSIAN AND NACE Standards. We procure the best steel and use state-of-the-art machinery resulting in better quality forged flanges and fittings. Exhaustive quality checks are done at every stage right from conception, designing and manufacturing ensuring high accuracy in terms of composition, mechanical properties, dimensions and delivery. We are also capable to provide special custom forgings as per our customers’ drawings and specifications.

Our primary objective is to provide quality service and fast delivery and our aim is to become your first choice as a flange and fittings provider. The impeccable collaboration from our design department to forgers to Quality Inspectors and packaging makes it possible. Technical competence and use of correct terminology is a key factor in our industry these days. Pipeline products are at times highly technical pressure retaining parts and should not be simply viewed as commodity items. By working with our customers and their clients in this way, we have become the pipeline equipment supply partner of choice to many.

Vision:

Vision:

- To continuously modernize, expand and technologically upgrade our products with a view to producing excellent and high-quality goods

- To match the changing needs of the customer and improve foreign exchange earnings for the country by promoting exports.

- To face Global competition and further improve Hilton’s Global presence fame and glory.

- To improve customer satisfaction and become cost effective

- To promote employees participation and to implement innovative methods for enriching the quality of life of all concerned.

Mission

To develop the relationship of trust with each customer because we believe in strong relations projected in future. Every day we are growing, as we don’t tend to forget that once a customer makes their first purchase with us, there is much more to be done in the customer relationship. HILTON knows that the first purchase is indeed just the beginning and that the real business value lies in retaining that customer. Quality, Efficiency, and Reliability are the 3 words which characterize our actions and summarize the HILTON PHILOSOPHY.

WHY US:

Our Values, business concept, strategies, objectives describe the Organizations overall mission, which is to create value for its customers and employees.

All our decisions are taken keeping the Customer in mind, since our success depends on their satisfaction. Before undertaking

an action we ask ourselves how this will add value to the customer and to the organization.

Hilton is a performance driven as well as a target oriented company whose performance is measured in all areas and at all levels, based on our deep understanding and knowledge.

Hilton can boast of a great team of people whose sole aim is satisfaction of their clientele. We are not merely responsible for our individual roles or departments, instead we share responsibility for the company as a whole and its results.

We are also venturing into aerospace industry by manufacturing turbine blades and in the railway industry by manufacturing forged wheels.

We continuously modernize, expand and technologically upgrade our products with a view :

- To produce excellent and high quality goods and matching with the changing needs of the customers, improve foreign exchange earnings for the country by promoting exports, face global competition and further improve our global presences’, fame and glory.

- To improve customer satisfaction, become cost effective, to promote employees participation and to implement innovative methods for enrichment of quality of life of all concerned.

Our Products

- Flanges & Forged Fittings

- Engineered parts

- Stainless steel flanges

- High pressure flanges

- Crank Shaft

- Body Bonnets

- Hydraulic Fittings

- Forged Components

- Christmas Tree Components

- Top Deck Cover

- Stub Ends

- Threaded Flanges

- Blind Flanges

- Weld Neck Flanges

- Socket Welded Flanges

Products

Railway Wheel Forgings & Manufacturing

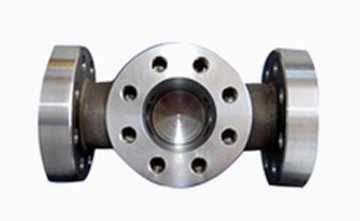

FLANGES

The ASME B16.5 – 1996 Pipe Flanges and Flange Fittings standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings for pipe flanges and flanged fittings.

The standard includes flanges with rating class designations 150, 300, 400, 600, 900, 1500, and 2500 in sizes NPS 1/2 through NPS 24, with requirements given in both metric and U.S units. The Standard is limited to flanges and flanged fittings made from cast or forged materials, and blind flanges and certain reducing flanges made from cast, forged, or plate materials. Also included in this Standard are requirements and recommendations regarding flange bolting, flange gaskets, and flange joints.

FORGED FITTINGS

The forged pipe fittings are suitable for fire fighting, HVAC, Oil & Gas Industries, Petrochemicals, High Pressure Lines, Railways, Shipping, Steel Plants, Boilers, Steam. Chemicals and Other Industrial Purposes. The fittings are tested for leakage at an internal hydraulic pressure of up to 1000 lbs, 3000 lbs & 6000 lbs. Forged Pipe Fittings are available in Socket Weld and Screwed / Threaded forms ranging from 0.25 Inches Through 3.00 Inches.

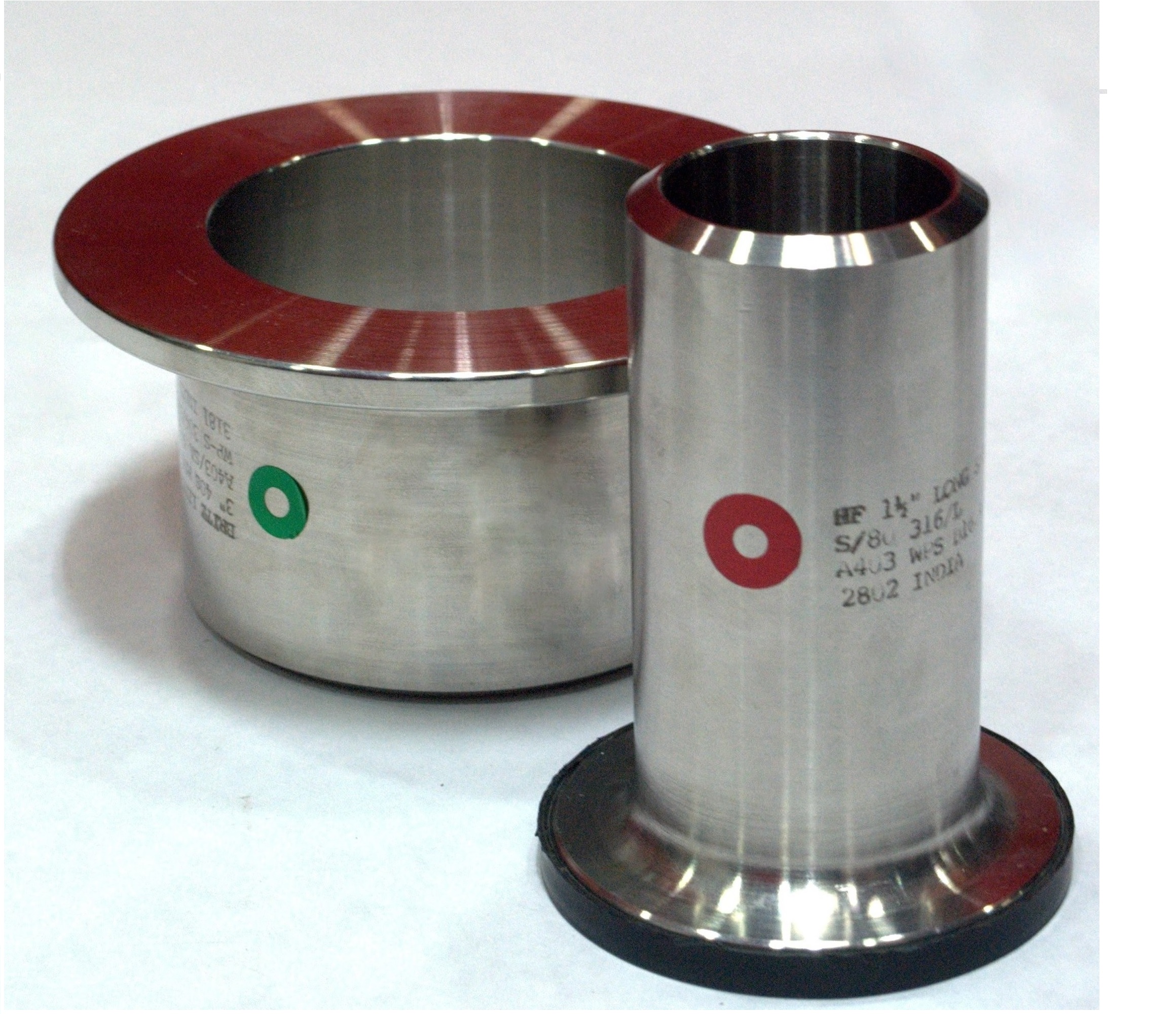

STUB ENDS

Forged stub ends are pipe fittings used to provide a flange-like connection in a piping system. They are specifically designed to be used with lap joint flanges, which slide over the stub end and are then rotated for alignment with other flanges.

The “forged” part of the name indicates that these fittings are created using the forging process, which enhances their strength and structural integrity through the application of high heat and pressure to the metal. Forging typically results in a product with improved mechanical properties and resistance to impact and fatigue.

Forging stub ends are available in long and short pattern lengths and in a variety of materials to match the pipe system they are used in, such as stainless steel, alloy steel, carbon steel, etc. They are advantageous because they make the line easy to disassemble for inspection, cleaning, or quick modification.

These fittings are often used in systems that require frequent dismantling for inspection and cleaning, and in applications where there is a need for a rotationally aligned system. They find extensive use in various industries, including petrochemicals, oil and gas, and water treatment plants.

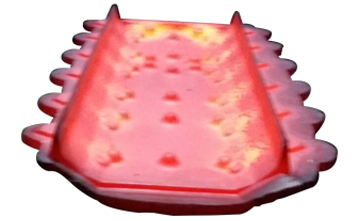

CHRISTMAS TREE COMPONENTS

We provide a flawless range of Bonnets to our clients available in numerous designs to fit the different requirements. These products are manufactured using quality raw material sourced from trusted vendors. We also offer customization solutions according to the need of the customer.

TOP DECK

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.