advertisement

Brand Information

What is the "pluming system"...

Plumbing is a system that conveys fluids such as liquid and gas through pipes. Joint is a device for connecting the pipe to another pipe or to change the direction(elbow), branch off(tees), reduce the inner diameter (reducer), and block the flow (cap) while the pipe is in a straight direction.

Benkan corporation originates from its predecessor , Nihon Benkan Industry corporation, which was established in 1947. Its main business was producing and distributing pipe joints called "Butt-welding fittings". Based on the high reliability, our fitting joints have been highly utilized in the power stations, gas distributors , oil refineries, shipyards, water treatment plants , and other key industries.

Especially, our "stainless steel piping" system drew attention as a versatile material with high durability, hygiene and toughness.

On the other hand, it required high welding skills and large space for its installation.

Development of Mechanical Joints

Benkan started to work on the development of "mechanical joints" to apply stainless steel pipes to ordinary piping in houses and other buldings.

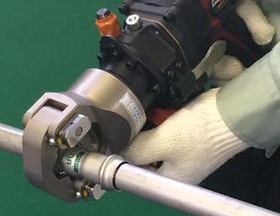

With mechanical joints and authorized press tools, we enabled a uniform quality of installation and a shorter construction time, unaffacted by the skills of the user.

"Molco joint" was released in 1975. Without compromising the advantages of stainless steel (high durability, strength and hygiene), it made possible an easy, speedy construction at a lower cost.

Since then, as the demand for stainless steel piping has increased, we have developped other products as “BK Joint”, “Double Press” which enhanced the safety function that supports the installation, and “EG Joint” which enables one-touch joining without the authorized press tool.

"Benkan of the stainless steel piping fame"

Currently, we are making various suggestions to various piping of each diversifying facilities such as detached houses, apartment houses, hotels, business buildings, intelligent buildings, hospitals and plants.

Mechanical Joint (MJ) factory is located in Ota, a city in southeastern Gumma.There are 77 employees working at the facility. MJ factory is divided into three sections: production, operation, and quality assurance.

The two subdivision the production section, manufacturing unit and test unit, is the operation centre of MJ factory, and contributes more than 40 years of knowledge and experience in plastic working of metal to our services.

Plastic working is a technique of applying pressure to materials to obtain desired shapes of products. This method enables to reduce the amount of materials used and the production cost. Also, it is an easy and efficient way of customizing product designs for our clients' commissions.

We do not consider the role of a factory should be limited to production. We invite factory visitors for them to experience the unique values we deliver. Your opinions would be greatly appreciated and help us further improve our services.

Please see how our Mechanical Joints are made, and check their quality with your own eyes! We are looking forward to your visit to our factory.

Our Advantage

- We offer everything plastic working can do.

We value creativity at work. - "A factory we can show"

Clean, organized workplace and good training for employees; these form the basis for product quality, cost reduction, work efficiency and safety of workers. - Improving quality assurance

We ensure no problems with our facility, tools, materials/parts and workers' behaviours to prevent defection.

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.