advertisement

Brand Information

Our History

Allied Engineering For Metal Industries was established in 2001 by the name Techtronic. Providing precision machining, gear manufacturing and mechanical machine parts for various types of industries.

Our Services

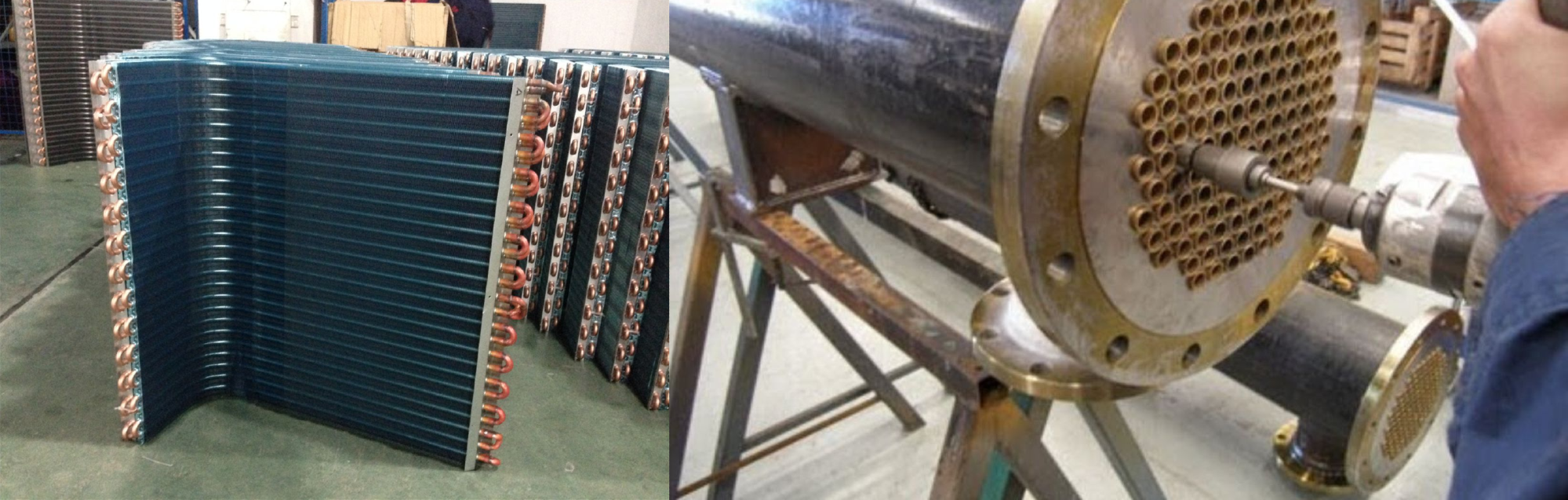

Supply, Installation, Upgrade of O & M Air cooled chillers, AHUs. Condensing &

Cooling coils Evaporative Condensers.

Re-Tubing, Repair, Upgrade Shell – tube & Air cooled Heat Exchangers

Annual maintenance contracts of all HVAC works.

Fabrication and Machining.

Material handling systems.

System Integration and Control panel installation and Termination.

Polyurea Coating Solution

We provide innovative & customized solution according to client’s equirements. Each

step among our manufacturing process is monitored and checked for accuracy

ensuring the very best in product quality

BUSINESS SECTORS

HVAC

- Supply, Installation, Upgrade of O & M Air cooled chillers, AHUs. Condensing & Cooling coils Evaporative Condensers.

- Re-Tubing, Repair, Upgrade Shell – tube & Air cooled Heat Exchangers

- SS 316l heat exchanger for food grade

- Annual maintenance contracts of all HVAC works.

HEAT EXCHANGERS

We manufacture Shell & Tube type Heat Exchangers in a wide variety of sizes & materials. Allied Heat Exchangers is a complete facility to design (Thermal and Mechanical) and manufactures complete range of Shell and Tube Heat Exchangers for cooling, condensing and heating application. We manufacture SS 316 Heat Exchangers for food grade industry.

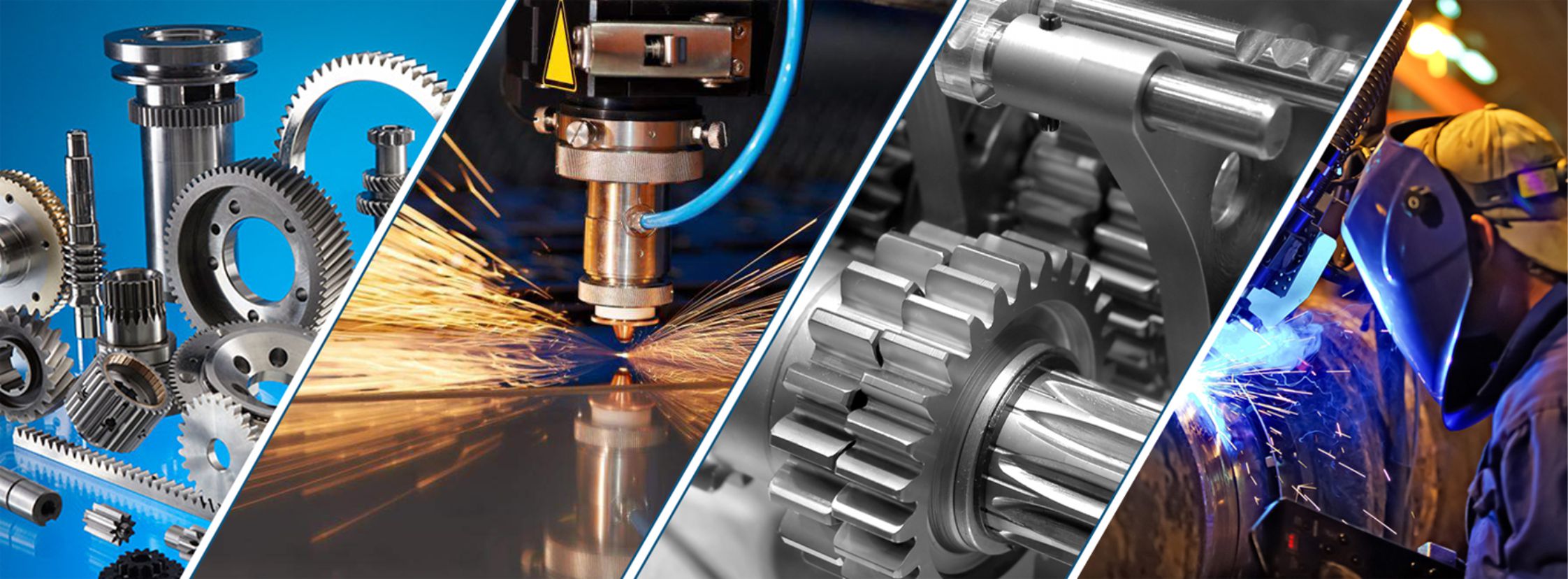

Machining & Fabrication

- Since 1995 Allied Engineering and Metal Industries (techtronics) has gained customers satisfaction and provided them precision machining and assembly for various type of industries. “MACHINIST WHO CARE ABOUT QUALITY AND ACCURACY”

- Our job is to do the best team work and efforts to accomplish the best technique for our clients, to comply with their needs with satisfactory manners. We are pleased to support any technical matter and happy to consult in major field. “where the right cut makes all the difference”

- We have complete tool room for fabrication shear blades, cutting tools, blanking dies, fabrication of machine rollers, machine parts & industrial maintenance etc.

- Teflon, POM, Nylon & kastamide parts

- Plastic molds, cutting & blanking tools etc.

- Self-lubrication bronze, brass lg1 / lg2 bronze bushes

- Manufacturing of industrial Machine Parts, Parts for production line, Gears, Rollers, Bushes & Bolts Etc.

- Fabrication of steel and SS Puddle flanges and steel pallets Etc.

- Our fabrication section equipped with water jet, plasma cutting machines etc.

- Baggage transfer dolly, and airport ground services and fabrication & supply of mobile ladder

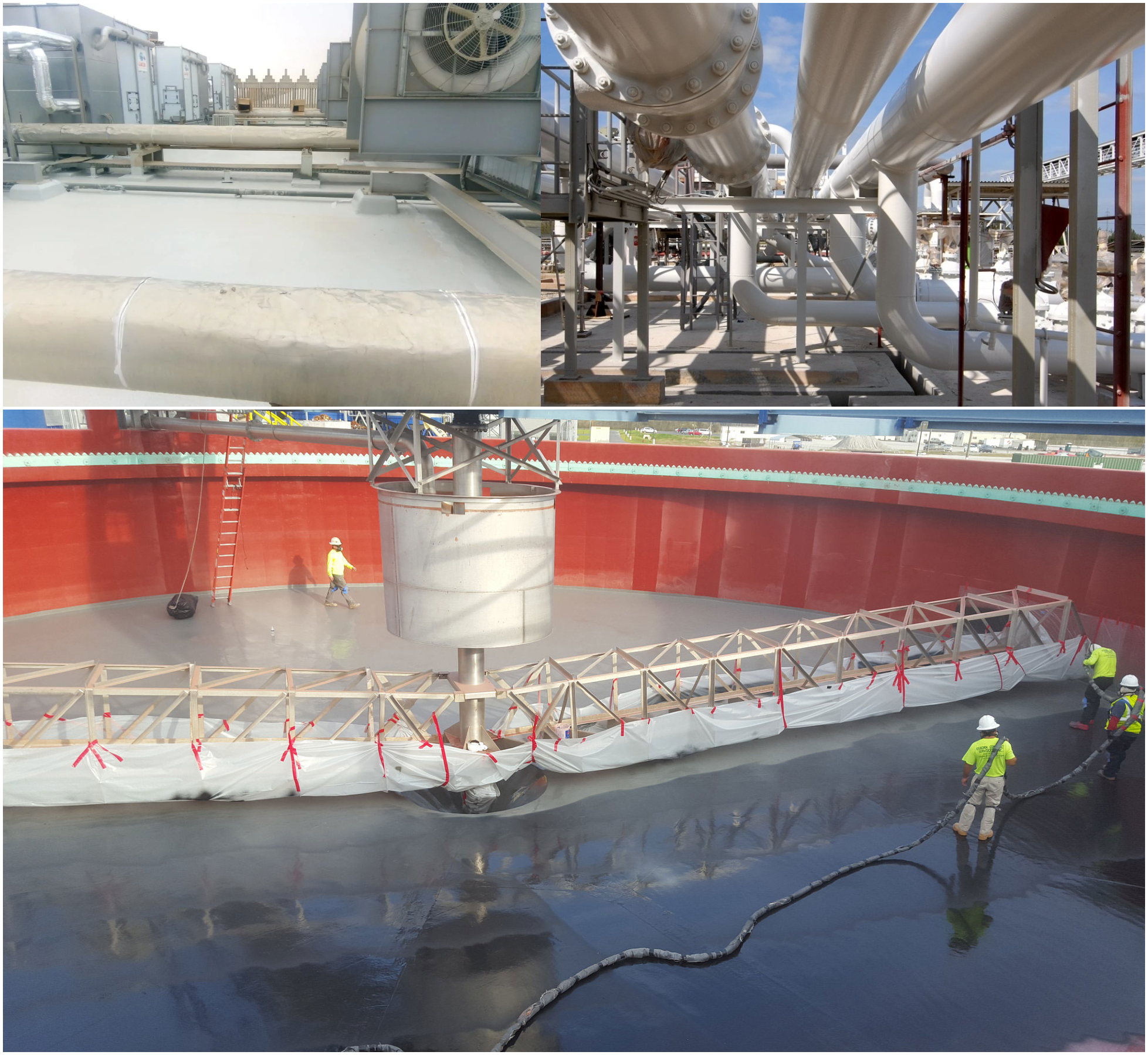

Polyurea Coating Solutions

Polyurea is a coating/lining technology that has been used successfully for four decades in many different applications all around the world. Polyurea solutions are more advanced than traditional coating systems, offering an array of advantages to the owner/contractor that cannot be achieved with any other coating system.

- ANTI-SLIP COATINGS

- CHEMICAL BUNDING

- CHEMICAL RESISTANT COATINGS

The Technology

Polyurea is not a specific coating system – it is a polymer technology with a vast range of product formulations, offering a range of solutions. No coating systems compare to polyurea when it comes to attainable physical properties from; high elongation to superior tensile strengths from hard abrasion resistant to soft impact resistant polyurea. One of polyurea’s major benefits is its fast set and return to service characteristics, Tack free can be as little as 10 seconds and can be open to light traffic within as little as an hour, returning an area to service many times faster than traditional coatings.

Advantages & Benefits

No VOC’s and little to no odour Temperature tolerant even in high humidity Extremely Flexible: excellent for both static and dynamic crack bridging Waterproof, resilient and seamless Fast application and cure times delivering reduced downtime Excellent bond strengths Resistant chemical resistance (subject to polyurea formulation) Low permeability, excellent sustainability and longevity Potable approved systems

The Application

Abrasion Resistance

Water Proofing

Hazardous Material Containment

Chemical Resistance

Floor Coatings

Antifouling Coatings

Energy Efficient Insulation

Corrosion Resistance

Refurbishment

Thermal Barrier Coating

Roofing Coatings

Pipe & Pipeline Coatings

Bridge Coating

Tank Linings & Tank Coatings

Waste Water Treatment Plants

Landscape & Water Containment

Aquarium Linings

Water Parks & Playgrounds

Manhole Lining

Fuel Storage & Containment

Swimming Pools & Ponds

The Technology

- Abrasion Resistance

- Water Proofing

- Hazardous Material Containment

- Chemical Resistance

- Floor Coatings

- Antifouling Coatings

- Energy Efficient Insulation

- Corrosion Resistance

- Refurbishment

- Thermal Barrier Coating

- Roofing Coatings

- Pipe & Pipeline Coatings

- Bridge Coating

- Tank Linings & Tank Coatings

- Waste Water Treatment Plants

- Landscape & Water Containment

- Aquarium Linings

- Water Parks & Playgrounds

- Manhole Lining

- Fuel Storage & Containment

- Swimming Pools & Ponds

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.